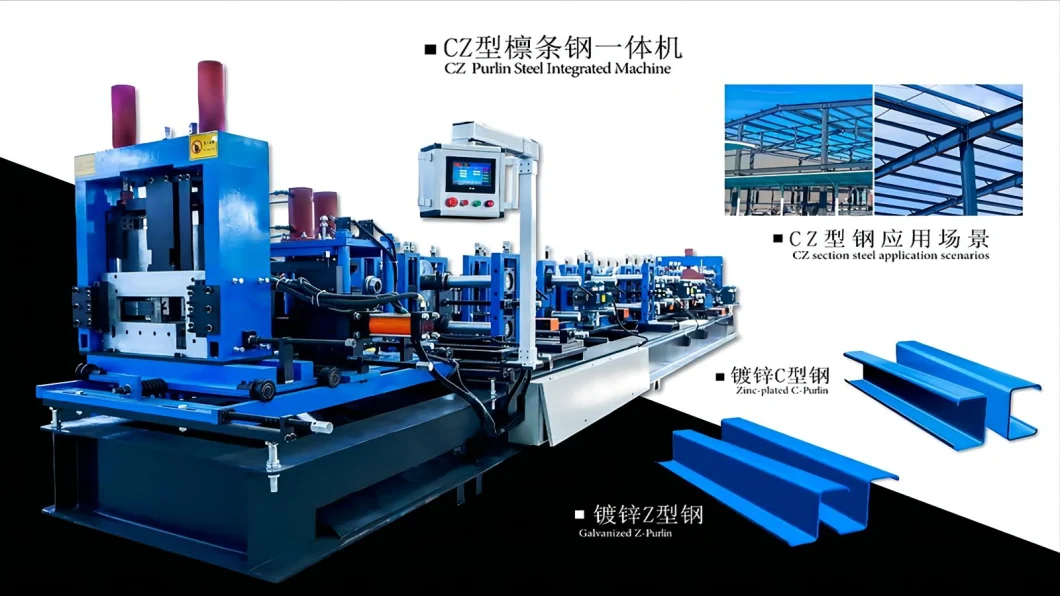

Xn Automatic C Purlin Cold Roll Forming Machine High Speed Steel C Channel Machine

Basic Info

| Model NO. | c purlin machine |

| Usage | Purlin |

| Transmission Method | Hydraulic Pressure |

| Color | as Customer Requirement |

| Size | 9500*1400*1350mm |

| Speed | 8-12m/Min |

| Forming Size | 80-300mm |

| Transport Package | Exported Packing |

| Specification | C purlin machine |

| Trademark | xninuo |

| Origin | China |

| HS Code | 8455221000 |

| Production Capacity | 200 Sets/Year |

Product Description

Xn Automatic C Purlin Cold Roll Forming Machine High Speed Steel C Channel MachineDetailed Photos

We are proffestional manufaturer,we can design the machine as customer requirement. Equipment components: Man-made uncoiler, Roll forming machine, computer control system, hydraulic control system, cutting. Our products are widely used in various industrial factory, civilian building, warehouse and easy steel building manufacturing, and have features such as nice appearance and durable.

Product Description

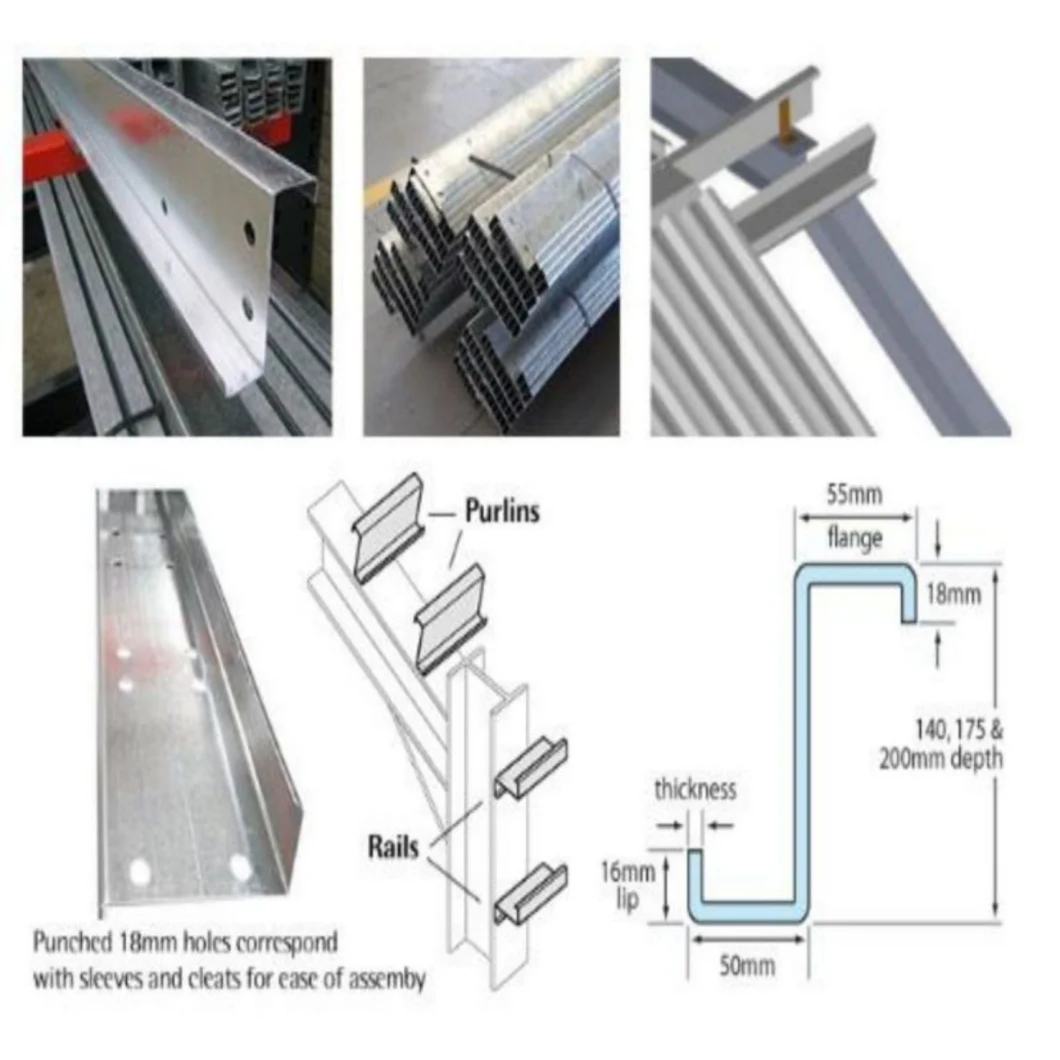

C shaped steel is a purlin and wall beam widely used in steel structure construction. It can also be combined into lightweight roof trusses and brackets. In addition, it can also be used for columns, beams and arms in the manufacture of light machinery. .It is widely used in steel structure workshops and steel structure engineering and is a commonly used construction steel. It is made by cold bending of hot rolled plate.

| Configurations | Manual Uncoiler ,Guiding Platform ,Coil Strip Leveler ,Main Body Of Roll Forming Machine, Electro-Motor, Hole-Punch Device ,Cutting Device ,Hydraulic Station ,PLC Control. |

| Control System | PLC Panasonic Inverter |

| Main Frame | 350mm H-Beam |

| Main Power | 11 kw |

| Pump Power | 7.5kw |

| Power Supply | 3-Phase,380V,50Hz |

| Forming Speed | 12-14m/min |

| Hydraulic Pressure | 18-20MPa |

| Forming Size | 80-300mm |

| Feeding Thickness | 1.5-3.2mm |

| Roller Station | 12 Stands |

| Roller Diameter | 90mm |

| Backboard Thickness | 18mm |

| Chain Size | 66mm |

| Cutter Standard | Cr12 mov |

| Roller Standard | Cr12 |

| Cr-Plating Size | 0.05mm |

| Overall Size | 9500×1400×1350mm |

| Total Weight | 6T |

It make the backboard of purlin machine, also make the holes on backboard. This milling machine can milling the backboard more level, hole place is more precious. This can make the roller more level after installing,and then the purlin will be more straight.

ELECTRICAL CONTROL

All the control system of our machines we make by ourselves. we have a professional engineer to design and make the control system. This can make sure the after-sale service, when customer have problem with control, we can solve it timely.

Packaging & Shipping

Company Profile

Hebei Xinnuo Roll Forming Machine, not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc. Strong technical resources are the most stable guarantee for our products' quality. We adopt computer software for design drawing, production drawing and installation drawing for steel construction equipment. We adopt advanced computer digital inspection and produce high quality light steel structure equipment. Our technical is updating day by day ! Our sales network covers all over China. We also sell products to the United States, Australia, the Netherlands, Germany, Ecuador, Bolivia, Thailand, Malaysia, Indonesia, India, the Philippines, Bangladesh, Nigeria, South Africa, Ethiopia, Syria, Libya, Ghana, Sudan, Saudi Arabia, the United Arab Emirates, Turkey, Azerbaijan and other markets. Our company has matured after-sale service network, we could provide efficient and satisfactory service for you throughout the period of our cooperation.If necessary, we can supply you with local technical support and send technicians to for installation and operation training.

F. Customer Visit And Exhibition

FAQ

1.How to play order :

Inquiry---confirm the profile drawings and price---confirm the PI---arrange the deposit or L/C---then OK

2.How to visit our company :

Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi(1 hour),then we can pick up you.

Fly to Shanghai Airport:By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5hours),then we can pick up you.

3.When we exported the machines :

We have beening making and exporting the machines since from the year of 1998.4.*Guarantee* : Lifetime maintenance guarantee.If some part of the machine is broken.We will supply the best original parts for the machine from our own factory. If the parts are damaged due to improper operation, buyer will pay for the freight.

5.*After-sales* : To give you the best after-sales service, the first give you video call with professional technicians , the second we send technicians to your country to repair the machine,The buyer shall bear all expenses, including visa, round-trip airfare and suitable accommodation, and pay the salary of usd 100 / day.6.Contact us:If you want to get more pictures or videos of the machines, feel free contact us.We will give you the best experience!

THANK FOR YOUT TIME !

WAITING FOR YOUR MESSAGE !