High Performance CNC Metal Z Purlin Frame Channel Roll C Steel Framing Profile Forming Machine

Basic Info

| Model NO. | FT-CZ |

| Usage | Roof |

| Transmission Method | Electric |

| Name | C Steel Framing Profile Forming Machine |

| Roller Material | Cr15 Steel |

| Shaft | 12 Stations |

| Diameter | 80mm |

| Language | English |

| PLC | Delta |

| Pump | 4kw |

| Cutter | Cr12 |

| Speed | 10-18m/Min |

| Thickness | 1-3mm |

| Transport Package | as Request |

| Specification | As design |

| Trademark | RFM |

| Origin | Hebei China |

| HS Code | 84552210 |

| Production Capacity | 500sets/Year |

Product Description

The advantages of High performance CNC metal Z purlin frame channel roll C steel framingprofile forming machine are as follows:

We can provide a C/Z Purlin roll Forming Machine with stable performance, excellent workmanshipand simple operation, which solves the production difficulties caused by the complicated operating systemof the workers during use, and meets the requirements of customers who want to hire low labor. All ofour machine wheels use C12 wheels. Some customers have doubts. What is the difference betweenC12 wheels and ordinary wheels? We have done destructive tests specifically on the wheels. Thebenefits of C12 wheels for machine products, because we are a cold bending industry, we mainly relyon the hardness of the wheels and his process to squeeze this sheet to achieve the shape the machinewants to produce, so for our product machine In general, the hardness of the wheel is one of the factorsthat can determine its long service life. Of course, we can't see it from the surface. Our wheels can reallybe tested. After all, no one wants to spend high. A lot of scrap iron was bought back for the price.

C purlin drawing:

Whole line components:

DecoilerMain forming machineControl boxHydraulic pumpTableProduct Parameters

Raw material | |

Material | Sheet, galvanized steel sheet, aluminum sheet |

Thickness of coil sheet | 1-3 mm |

Machine details | |

Roller material | High grade NO. 45 forged steel with 0.05mmhard chrome plating |

Shaft material | High grade NO. 45 carbon wrought steel |

Cutting blade | Cr12 mould steel with quenched treatment |

Diameter of shaft | 90mm |

Forming steps | 12 rows |

Productivity | 20-25m/min |

Hydraulic station power | 22 KW |

Hydraulic pressure | 10-12MPa |

Controlling system | Famous PLC computer control |

Material of cutting table | Cr 12 mould steel with quenched treatment |

Appearance size | 7500mm*1150mm*1510mm |

Weight | 6-7 tons |

Hydraulic oil | 40# hydraulic oil |

Electric tension | 380V 50 Hz 3 Phase or as your requirements |

Company Profile

FAQ:

Q1. What's your payment terms and delivery time?A1: 30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspect the machine welland before delivery. Of course your payment terms like L/C are acceptable. After we get down payment, we will arrangeproduction. About 30-45 days for delivery.

Q2. Do you have after-sales support?

A2: Yes, we are happy to provide advice and we also have skilled technicians available across the world.

Q3. Do you sell only standard machines?

A3: No, most of our machines are built according to customers specifications, using top brand components.

Q4. What will you do if the machine is broken?

A4: We provide 24 months free warranty and free technical support for the whole life of any machine. If the broken partscan't repair, we can send the new parts replace the broken parts freely, but you need pay the express cost by yourself. If itis beyond the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the equipment.

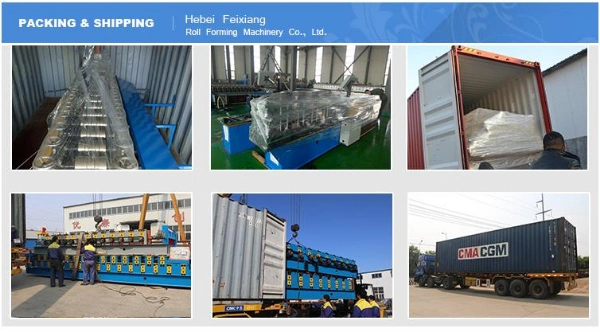

Q5. Can you be responsible for transport?

A5: Yes, please tell me the destination port or address. we have rich experience in transporting.

Q6. How to visit your company?

A6: 1) Fly to Beijing airport, By high speed train From Beijing Nan to Cangzhou Xi (1 hour). 2) Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can meet you.