Hydraulic Precision Crimping Extruder Roll Forming Machine

Basic Info

| Model NO. | Crimping Machine Tool |

| Material | Cold Rolled Steel,Pre-Painted Steel |

| Controller | Siemens PLC |

| Thickness | 0.3-0.7mm |

| Width | 100-1250mm |

| Max.Forming Speed | 15 M/Min |

| Main Motor Power | 4 Kw |

| Machine Size(L*W*H) | 2500mm * 1500mm* 1500mm |

| Warranty | 1 Year |

| After-Sales Service Provided | Engineers Available to Service Machinery Overseas |

| Transport Package | Sea Worthy Fixed by Wire Rope, Wooden Blocks |

| Specification | CE Standard, ISO 9001-2008 |

| Trademark | WILLING INT′L |

| Origin | China R. P |

| HS Code | 84552210 |

| Production Capacity | 150 Sets Per Year |

Product Description

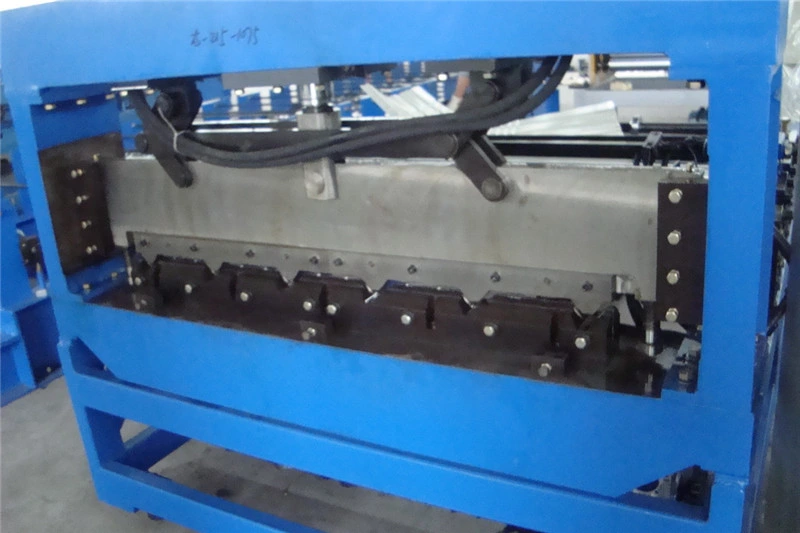

Hydraulic Crimping Machine Metal Making Machinery

The crimping machine consists of infeed guide, crimping die, hydraulic station, PLC control console.

Technical Parameters

| Material | Cold rolled steel /pre-painted steel/ galvanized steel /aluminum |

| Profile of press | C *(0.3~0.7)mm ("C" is the width of corrugated sheet already produced) |

| Thickness | 0.3-0.7mm |

| Width: | 100~1250mm |

| Line speed | max. 15m / min. |

| Machine size | 2500mm * 1500mm* 1500mm(L*W*H) |

| Motor power | 4 kw |

| Controlling | PLC console, Siemens brand electric parts |

| Roller material | Cr12 |

| Roller Diameter | 350mm |

| Width of roller | 1300mm |

| Embossing pattern | as per customer's sample |

Material of Main Equipment

| Roller Material | High grade S45C forged steel, coated with hard chrome. |

| Active Shaft Material | High grade S45C carbon wrought steel, diameter 76mm. |

| Electric Elements | PLC control console, touch screen and transducer, from Siemens.Other elements, from Schneider Electric, Germany |

| Cutter Blades | Cr12MoV steel with quenched treatment, hardness HRC58~61,wear-resistance, good steel structure, long life. |

Packaging & Shipping

1.One 20ft container for loading one set machine with manual decoiler; 2.The whole Wiped Anti Rust Oil, PLC controller covered by foam film; 3.Spare parts and some small parts packed in plastic tooling box; 4.All Components Fixed by steel wire with Container.

Company Profile

FAQ

- Q:Are you a manufacturer?

- A:Yes absolutely. Welcome a lot for your visiting to us.

Q:What's the delivery time?

A:Normaly will take 60days

Q:Do you have after-sale support?

A:Yes, we're always here for giving you advice and support for technical details since we have senior technician.

Q:Is there quality control when manufacturing the lines?

A:Yes, we have a group of team who will be responsible for quality control from laying off the raw material, processing the rollers and the other parts, make treatment on the roller surface and shaft, assembling, testing and packaging.

Q:What's your strength comparing to the other supplier?

A:We'll supplying you the best quality and service. We'll give you good advise beyond your requirements. The lines are easily for installation and with low mantenance requirements.