Category

Stainless Steel Metal Roofing Roll Former for Roll Forming Machine Yx28-207-828/1035

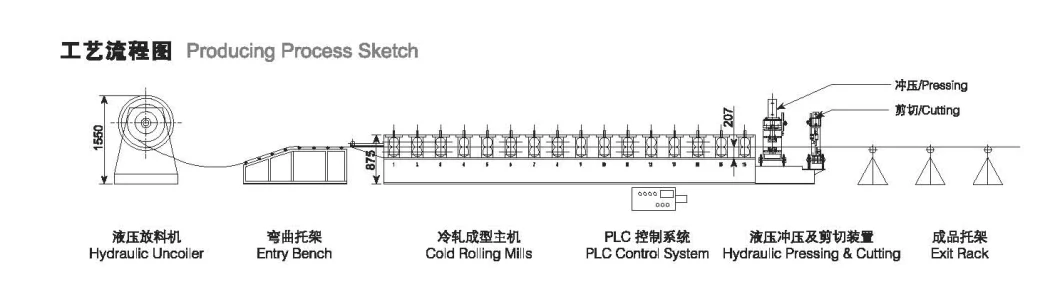

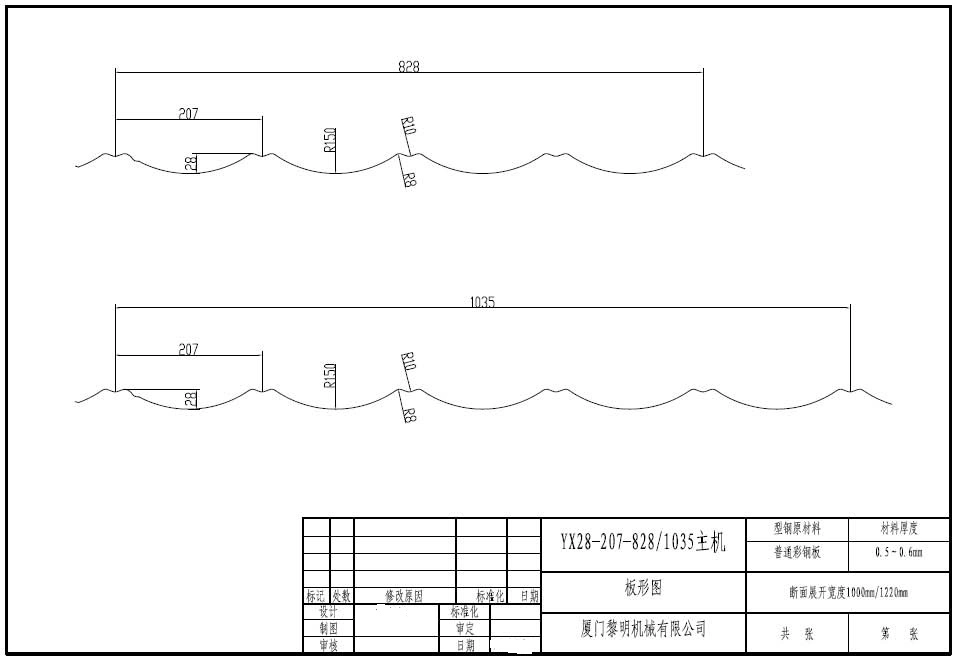

This Producing Process Sketch As Below Picture: This Profile Drawing As Below Picture: General Parameter Machine Compone

Basic Info

| Model NO. | YX28-207-828/1035 |

| Customized | Customized |

| Feeding Width | 828/1035 mm |

| Effective Width | 1000/1200 mm |

| Thickness | 0.4-0.6 mm |

| Yield Strength | 245-300 MPa |

| Transport Package | 40gp*1 |

| Specification | 12T |

| Trademark | Xiamen Liming |

| Origin | Fujian, China(Mainland) |

| Production Capacity | 60 Set/Month |

Product Description

This Producing Process Sketch As Below Picture:

This Profile Drawing As Below Picture:

General Parameter

| 1 | Item | Parameters |

| 2 | Model NO. | YX28-207-828/1035 |

| 3 | Material | Pre-painted galvanized sheet |

| 4 | Thickness | 0.4-0.6 mm |

| 5 | Yield Strength | 245-300 MPa |

| 6 | Feed Width | 1000/1200 mm |

| 7 | Effective width | 828/1035 mm |

| 8 | Roll Stages | 16 Stages |

| 9 | Shafts Diameter | ф75 mm |

| 10 | Main Motor Power | 5.5 KW |

| 11 | Hydraulic Group Power | 11 KW |

| 12 | Max. Line Speed Of Roll Former | Approx.18-20 m/min |

| 13 | Electric Standard | According to local voltage |

Machine Components

A. 6TON*1250MM HYDRAULIC UN-COILERHydraulic system expand coil inner hole, Pump motor: 3KWFrequency Inverter to regulate turning speed, Motor: 3KWLink-connect expanding systemTo fit with the Max. Line speed of roll former: 25mpmAutomatic stopping device, Load capacity = Max.5+1TonsSupport arm maintain at the end of the main shaft for extra one ton capacityDouble level expanding palms with two coils bore variations of 480mm-530mm for Palm 1 and 580mm-610mm for Palm 2Coil width = Max.1250mmB. Entry roller & Manual Pre-shearing device Un-powered Smart cut control, to cut off the end of the final piece of sheet onlyWorking thickness up to 0.8mm

C. Cold Rolling Mills Feeding section with guide;Gear/Sprocket driving;16 stages to formWall-plate-frame design

Rollers manufactured from 45# steel,CNC lathes,hard chrome coating

Shafts Diameter=ф75mm, Precision Machined

Main motor =5.5KW,Frequency speed control

Max line speed of roll former: Approx.18-20m/min

Protection Mesh Cover (full mesh type) Above Roll-former To Avoid Hands Go Inside

E. Hydraulic Stair-Drawing & Cutting M/CStop to press, Stop to cut; Post cut, No Blanking cutPump motor =11KW, Cutting pressure = Max. 8MpaCutting tool material: Cr12, Heat treatmentStair depth=14mm

F. PLC Control System

Control the quantity & cutting length automatically;Combined with: PLC, Touch Screen, Inverter (SIEMENS), Encoder (Omron), REMOTE CONTROL etc

Cut-to-length tolerance≤±2 mm Control Voltage 24V

G. Product Rack Un-powered, 3 units After-Sale ServiceIn correct operation & maintaining, the machine is guaranteed for one year since leaving our factory excludes the electric elements.Installation:If installation is needed, WE will dispatch a technician to the buyer's factory abroad to assist regulating the machine with charge free. The buyer should assist US to get the Chinese technician's visa and should pay for the roundtrip air ticket and the local accommodation.If installation is needed, the buyer shall make the following preparation before arrival of technicians.

Terms Of Trade1.Package & Shipment: Facility water-proof packing, Control cabinet packed in wooden packing.2.Payment: 30%payment by T/T is required as deposit within a week since the contract signing date.70% payment by T/T is required before the machine be send out of factory.