Category

Sheet Metal Roof Roll Former with High Speed

Package size per unit product 12580.00cm * 1960.00cm * 1750.00cm Gross weight per unit product 7600.000kg 1.The Chart of

Basic Info

| Processing Object | Metal |

| Molding Style | Forging |

| Molding Technics | Pressure Casting |

| Application | Machinery Parts |

| Machining | Machining Center |

| Material | Aluminium |

| Surface Treatment | Hard Chrome Coated |

| Forging Tolerance | +/-0.1mm |

| Standard | CE/ISO 9001:2000\ISO 9001:2008 |

| Certification | CE, RoHS, ISO 9001:2000, ISO 9001:2008, CE, ISO |

| Tile Type | Glazed Steel |

| Condition | New |

| Customized | Customized |

| Usage | Floor |

| After-Sales Service | 1 Year Warranty |

| Warranty | 1 Year |

| Transmission Method | Motor Drive |

| Thickness | 0.4-0.6mm |

| Transport Package | 40gp′*1+20gp+1 |

| Specification | 6T |

| Trademark | LIMING MACHINERY |

| Origin | Fujian, China (Mainland) |

| Production Capacity | 60/Month |

Packaging & Delivery

Package size per unit product 12580.00cm * 1960.00cm * 1750.00cm Gross weight per unit product 7600.000kgProduct Description

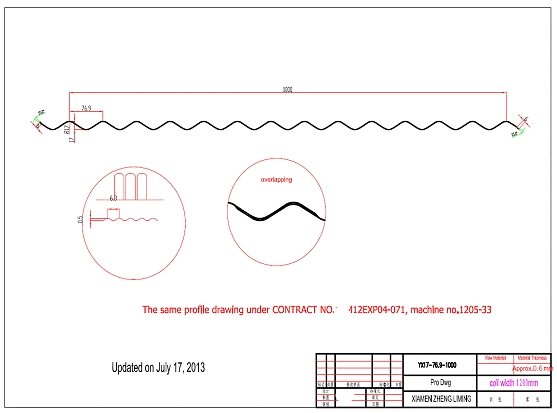

1.The Chart of Process FlowYX18-76-1000 Roof Profile:

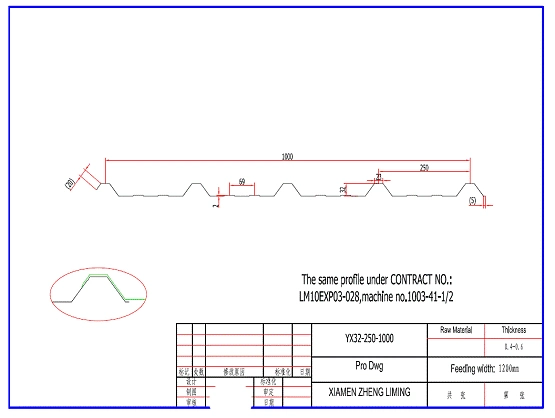

YX32-250-1000 Roof Profile:

2.Technical ParametersThe main technical parameters are for your inference only. Only if you provide the profile required or the real objects of sectional materials, and we will offer the accurate parameters.

| 1.5Tons un-coiler | |

| Description | There are different choices, please turn to the catalogue of un-coiler |

| 2. Manual Pre-shearing device | |

| Function | un-poweredDual LevelingSmart cut control, to cut off the end of the final piece of sheet only |

| Shearing Thickness | Up to Max. 0.6mm (if thickness > 0.6mm, then hydraulic pre-shearing device or electric pre-shearing device instead ) |

| 3. The general machine parameter | |

| Suitable roll forming material | Color steel sheet or galvanized steel sheet |

| Thickness | 0.4mm-0.6mm |

| Feeding width | 1200mm |

| Frame design | Wall-plate-frame-design |

| YX18 Roll stages | 20 stages |

| YX32 Roll stages | 19 stages |

| Material of forming roller | 45# steel, CNC lathes, Hard Chrome Coated |

| Shafts Diameter | Φ75/Φ95mm |

| Main motor power | 11KW with reducer |

| Max. Line speed of roll former | 15m/min (Higher speed is available, depends on the specification required by the buyer) |

| Attention:The two levels can't be run at the same timeManual Clutch to switch the driven systemThe two profiles share one un-coiler/ base frame/ main motor for roll former/ hydraulic cutting carriage/PLC control system | |

| Hydraulic group power | 7.5KW |

| Material of cutting blade | Cr12, hear treatment |

| Electric Standard | 380V /50Hz/3PH or as the customer's requirements |

| Major Color of Machine Painted | RAL 5015 (Blue) or as per customer's requirements |

| 4. PLC Control system | |

| PLC | (ABB brand is available if required) |

| Touch Screen | (ABB brand is available if required) |

| Inverter | (ABB brand is available if required) |

| Encoder | Omron brand |

| 5.Product rack | |

| Description | un-powered, 3 units |

Option:

| |

| 6. Service after sell | |

| In correct operation & maintaining, the machine is guaranteed for one year since leaving our factory excludes the electric elements.Installation:(1) If installation is needed, Liming (the seller) will dispatch technician to the buyer's factory abroad to assist regulating the machine with charge free. The buyer should assist Liming to get the Chinese technician's visa and should pay for the roundtrip air ticket and the local accommodation.(2) If installation is needed, the buyer shall make the following preparation before arrival of technicians.a) Position the machine in the buyer's factory.b) Prepare necessary electric wiring.c) Prepare material of trial running.d) Provide labors for assistance and installation during installation.e) If possible, One Chinese-speaking interpreter so that the communication between the buyer and seller's technician will go smoothly. | |

| 7. About us | |

| Please visit the web site: liming2018.en.made-in-china.com for detailed information | |

Below pictures are for your reference only

After-Sale Service

In correct operation & maintaining, the machine is guaranteed for one year since leaving our factory excludes the electric elements.

Installation:If installation is needed, WE will dispatch a technician to the buyer's factory abroad to assist regulating the machine with charge free.The buyer should assist US to get the Chinese technician's visa and should pay for the roundtrip air ticket and the local accommodation.If installation is needed, the buyer shall make the following preparation before arrival of technicians.

Terms Of Trade

Package & Shipment: Facility water-proof packing, Control cabinet packed in wooden packing.Payment: 30%payment by T/T is required as deposit within a week since the contract signing date.70% payment by T/T is required before the machine be send out of factory.