Double Row C U T Ceiling Channe Grid Wall Angle Drywall Corner Light Keel Steel Frame Roll Shaped Profile Stud and Track T Bar Roll Forming Making Machine

Basic Info

| Model NO. | Keel-ZTRFM |

| Speed | 12m/Min |

| Coil Thickness | 0.3-1.5mm |

| D.Shaft | 80mm |

| Main Frame | 350h |

| Power | 12kw |

| Weight | 6.5t |

| Thickness of Material | 0.3-1.5mm |

| Dimension | 7500X1500X1910mm |

| Voltage | 380V 3phase 50Hz |

| Material of Roller | High Grade 45# Forged Steel Plated with Hard Chrom |

| Material of Cutting | Cr12 Mould Steel with Quenched Treatment |

| Workers | 1-2 Only |

| Transport Package | Container |

| Specification | 40ft |

| Trademark | GEIT-ZTRFM |

| Origin | China |

| HS Code | 8455221000 |

| Production Capacity | 200sets/Year |

Product Description

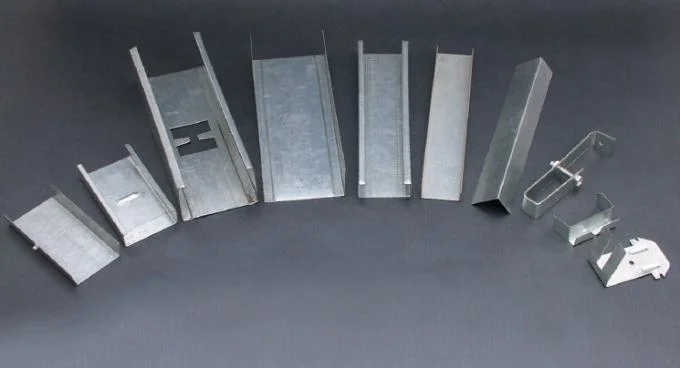

Steel light keel plate roll forming machine/steel tracks light keel hat section cold roll forming line

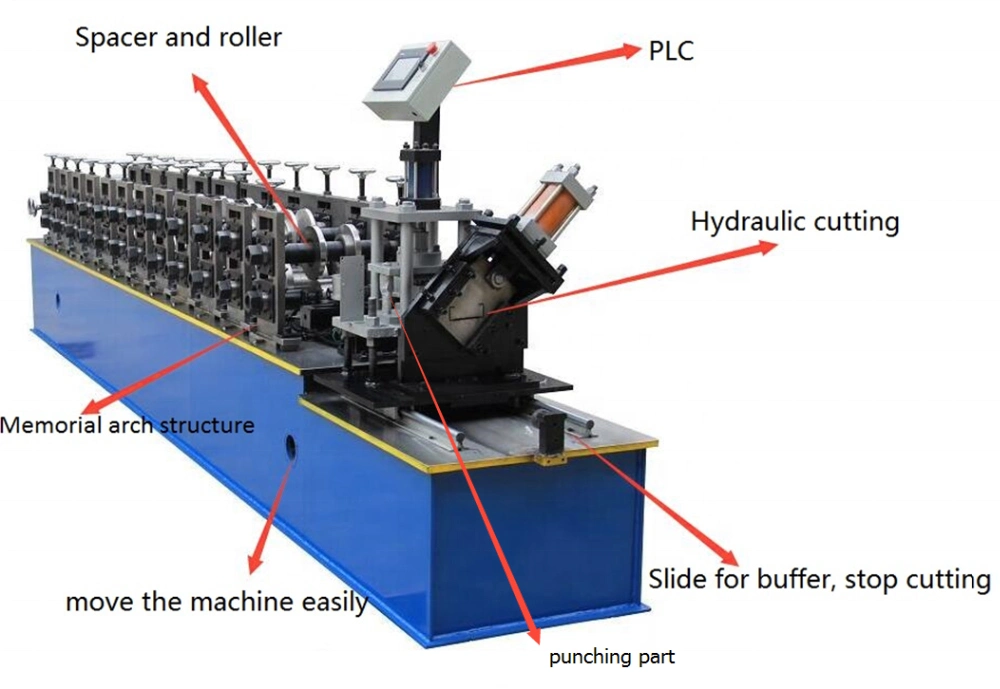

This shape profile roll forming machine is fully automatic and high speed producing continuously, one set of forming rolls can produce various sizes of Stud and Runner just by simply and easily changing the spacers, this enables the production of different sizes products on the same rollers.

A drywall stud and track roll forming machine usually consists of manual decoiler, a feeding guide unit, a punching tool, a roll forming unit, a cutting unit, a transmission unit, a hydraulic unit, a control unit, and run-out tables. Under PLC control system, this drywall stud and track roll forming machine fully automatically produces 4-6 metal c studs or u tracks out of galvanized steel

Product Parameters

| No. | Light Keel Roll Forming Machine | |

| 1 | Suitable material | Color steel sheet ,galvanized steel sheet, aluminium sheet |

| 2 | Width of material | 1000mm or as need |

| 3 | Thickness of material | 0.3-1.5mm or as your needs |

| 4 | Working speed | 0-25m/min |

| 5 | Electrical control system | PLC control system |

| 6 | Shaft diameter | 80mm/75mm |

| 7 | Dimension | 7500x1500x1910mm |

| 8 | Weight | About 6 T |

| 9 | Voltage | 380V 3phase 50HZ or as the customer's requirements |

| 10 | Material of roller | High grade 45# forged steel plated with hard chrome plating |

| 11 | Material of cutting | Cr12 mould steel with quenched treatment |

| 12 | Working time | Can be 24 hours |

| 13 | Workers | 1-2 only |

Product Description

Detailed Photos

Certifications

Packaging & Shipping

Company Profile

GEIT GROUP is a professional manufacturer and exporter which is concerned with the design, development and production of cold roll forming machines.The factory located in Botou-Hebei, which focus on designing and manufacturing of different types cold roll forming machines.