Category

Customized Metal Ibr Roof Roll Former Forming Machine

Overview Package size per unit product 650.00cm * 140.00cm * 130.00cm Gross weight per unit product 2700.000kg Product P

Basic Info

| Model NO. | Customized Metal Ibr Roof Roll Former Forming Mach |

| Certification | ISO, BV |

| Condition | New |

| Customized | Customized |

| Usage | Roof |

| Transmission Method | Chain Driving |

| Product Name | Metal Roofing Double Deck Rollfomer Machine |

| Materials | PPGI / Gi/ PPGL/ Colored Coated Steel / Aluminium |

| Finished Profile | Ribtype/ Longspan/ AG/ Pbr/R Panel |

| Sheet Type | Steel Metal Roof and Wall Sheet Profile |

| Sheet Profile Size | Customized According to Different Country |

| Applicable Industries | Hotels, Garment Shops, Building Material Shops |

| Key Selling Points | High Productivity |

| Machinery Test Report | Provided |

| Video Outgoing-Inspection | Provided |

| Finished Roof Profile | Customized |

| Machine Type | Customized |

| After-Sales Service Provided | Online Support Video Technical Support |

| Advantage | Easy Installation, Full Automatic Easy Operation |

| Control System | Full CNC Automatic Control |

| Operating Procedures | We Will Send You Operation Book with The Machine |

| Transport Package | Exporting Package |

| Specification | Cutsomized |

| Trademark | N/M |

| Origin | Botou, China |

| HS Code | 84552210 |

| Production Capacity | 2000 Sets/Year |

Packaging & Delivery

Package size per unit product 650.00cm * 140.00cm * 130.00cm Gross weight per unit product 2700.000kgProduct Description

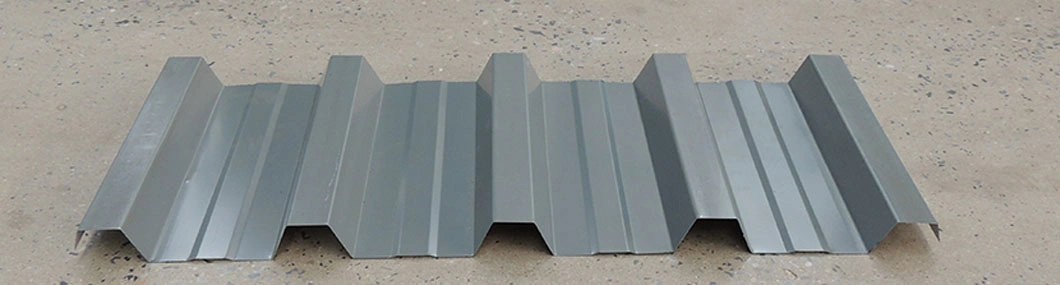

Product Parameters Customized Metal Ibr Roof Roll Former Forming MachineOur Customized Metal Ibr Roof Roll Former Forming Machine for different models based on different designs or customer's samples . It is a machine produce building material of metal roof, the products are widely used as the roof and wall of factory,warehouse, garage, gymnasium, exhibition center.It has many advantages, such as easy installation, short building period, beauty, light weight but high strength.

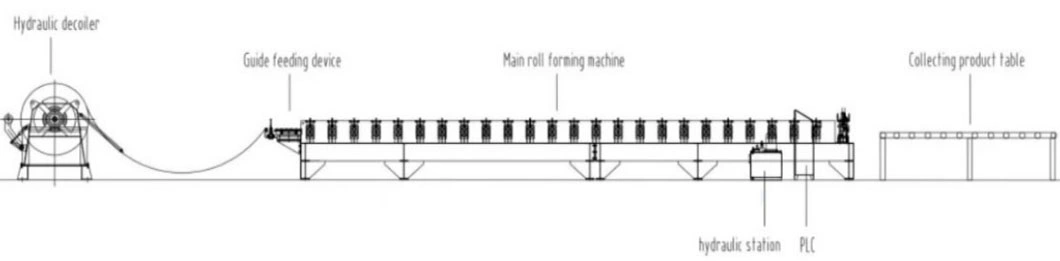

1, Working Flow Of Customized Metal Ibr Roof Roll Former Forming Machine :

De-coiler-→Level device -→Main roll forming machine-→Hydraulic cutting-→ Run out table

2, Customized Metal Ibr Roof Roll Former Forming Machine Details :

| Working material: | Color Steel Sheet Coil/Glavanized Steel Coil |

| Feeding Width : | 914mm-1450mm ( Can Customize it according client's requirement) |

| Effective width : | According to agreed sheet profile drawing |

| Thickness : | 0.3-0.7mm |

| Machine Weight : | About 3.0Tons |

| Dimension of machine: | About 6.5m*1.4m*1.3m |

| Shaft station : | 13 Stations |

| Rolling speed : | 8-20m/min |

| Transmission: | By chain |

| Size of Chain : | 1.0 inch |

| Shaft materials : | 45# Steel plated hard |

| Material of Roller: | 45# Steel plated hard |

| Cutter materials: | GCr12 steel with quenched treated 60-62°C |

| Voltage: | 380V/50HZ,3PH ( also can do based on your requirement) |

| Material of Frame : | 300 H steel welding |

| Thickness of middle plate: | 16mm |

3, The Finished Prouct Of Customized Metal Ibr Roof Roll Former Forming Machine :

4, Cutting systerm Of Customized Metal Ibr Roof Roll Former Forming Machine :

5, Feeding Device Of Customized Metal Ibr Roof Roll Former Forming Machine :

6, Our Company Exhibition :Packaging & ShippingCertifications

Q: Do you have after-sales support? A: Yes, our company provide technical support. If You need our technical engineer to go to your factory, we can send our engineer to you fatory.2

Q: How to visit your company? A: Fly to Beijing airport or Tianjin airport, we can pick you up. 3.

Q: How to get a quote? A: Be sure to give me the profile and tell us the materials thickness. If not, I'll give you some advice. Let us know if you have other requirements, such as your desired speed, power and voltage.4.

Q: Are you a trading company or a factory? A: We are factory. Welcome to visit our workshop.5.

Q: Can you take care of shipping? A: Yes, please tell me the port of destination or address. We have rich experience in transportation.6.

Q: How long can the machine be manufactured? A: Normally, an ordinary roll forming machine can complete it within 45 working days. If you need a machine urgently, we can do it for you in less than a month