Category

Cuadro 30X15 Steel Wall Panel Roofing Sheet Deck Cold Roll Forming Machine Price

Overview Package size per unit product 13500.00cm * 900.00cm * 1550.00cm Gross weight per unit product 10000.000kg CUADR

Basic Info

| Model NO. | 30x15 |

| After-sales Service | 20 Year |

| Warranty | 1 Year |

| Tile Type | Colored Steel |

| Certification | CE, ISO |

| Condition | New |

| Customized | Customized |

| Usage | Roof, Wall |

| Transmission Method | Hydraulic Pressure |

| Color | Blue or as Customer′s Request |

| Material Width | 400mm |

| Voltage | 380V -415V |

| Electric Components | Delixi or Chnt |

| Touch Screen | Delta |

| Transducer Motor | 5.5kw |

| Transducer | Delta |

| Driving Motor Brand | Lichao |

| Transport Package | Nacked |

| Specification | 14.5*0.9*1.55m |

| Trademark | zz |

| Origin | China |

| HS Code | 8455221000 |

| Production Capacity | 50-100sets/Year |

Packaging & Delivery

Package size per unit product 13500.00cm * 900.00cm * 1550.00cm Gross weight per unit product 10000.000kgProduct Description

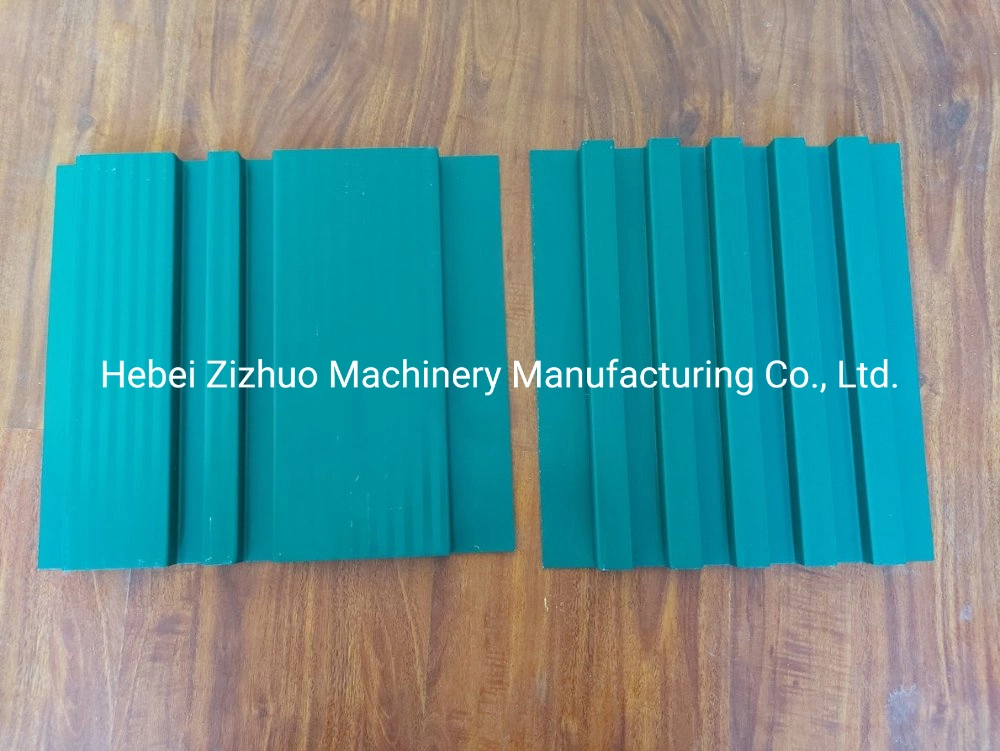

CUADRO 30x15 Steel Wall Panel Roofing Sheet Deck Cold Roll Forming Machine PriceProfile drawing

Product Parameters

| No. | Item | Parameter | Remark | |

| 1 | Suitable material | Type | Color steel, galvanized steel | |

| Thickness(mm) | 0.35-0.7mm | Test material standard 0.45mm | ||

| Yield strength (Mpa) | ≤300mm | |||

| Width (mm) | About 400-500mm | |||

| 2 | Forming speed | About 20 m/m | Not include cutting time | |

| 3 | Motor of forming system (kw) | 5.5kw | Depends on final design | |

| 4 | Hydraulic station power(kw) | 4kw | Depends on final design | |

| 5 | Voltage requirements | AC380V, 50Hz, 3phase | According to the customer's request | |

| 6 | Roller material | #45 steel with heat treatment 58-62 degrees | ||

| 7 | Shaft diameter | 70mm solid | ||

| 8 | Control system | PLC with touchscreen | Delta brand | |

Detailed Photos

Packaging & Shipping

Exhibition and customers

Why choose us

1. Unique coil processing solutions for metalworking?

Hebei Zizhuo Machinery Manufacturing is aimed at providing our customers with the best quality metal rolling automation solutions and after-sales service.2. Equipment research and developing

Our company commits to providing customized coil processing solutions according to each customer's specific metalworking process. With an experienced technical team and continuous research investment, we are capable to offer coil handling solutions that meet higher international standards.

3. Manufacturing quality control

With precision machine tools and skilled workers, from spare parts preparation to equipment assembly, our machine can offer real-time manufacturing updates for our valued customers.From raw material control, spare parts inspection, and machine assembly, our factory implements a strict quality control process. We commit to offering coil performance.ll work is just for making sure all the products of machines are qualified.