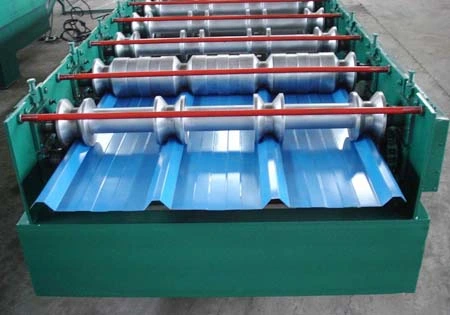

Corrugated Metal Sheet Cold Rolling Purlin Roll Forming Machine

Basic Info

| Model NO. | 0.20-0.80mm |

| Production Scope | Product Line |

| Automatic Grade | Automatic |

| Warranty | 1 Year |

| Material | Coloured Glaze |

| Color | Blue |

| Customized | Customized |

| Type | Metal Wall Forming Machine |

| Shape | Irregular Cuboid |

| Commodity | Roof Sheet Roll Forming Machine |

| Use | Roofing |

| Material Thickness | 0.3-0.8mm or Customized as Your Request |

| Color of Machine | Blue or as Your Request |

| Forming Speed | 13-15m/Min |

| Hydraulic Station Power | 3kw |

| Suitble Material | Galvanized / Galvalume /Color Coated Steel |

| Transport Package | Standard Packing to Export. |

| Specification | CE and ISO9001: 2008ukas |

| Trademark | As your needs |

| Origin | Shandong, China |

| HS Code | 845221000 |

| Production Capacity | 30 Set/Sets Per Month |

Product Description

Corrugated roof Profile Sheet Making Machine-roll forming machine

Color forming machine used color-coated plates, Can be formed various of corrugated panels. it is suitable for industrial and civil building, warehouse special building, large span steel structure building roof, wall etc, with light, high strength

It is convenient, fire prevention, rainproof, long life and maintenance etc, have been widely used in the construction project

Panel Picture

How to build a different workshop and more beautiful than others?Choose our big wave Horizontal Installed Corrugated Wall panel forming machine

corrugated iron sheet making machine

A.General details

| Suitable Material | HRB60 or equivalent(PPGI/PPGL/GI/GL) |

| Materials thickness | 0.3mm-0.8mm |

| Dimension | About 7.2*1.3*1.1m(L*W*H) , as per the drawing |

Length of the Sheet | can set the length according to your infact need. It is controlled by PLC which can ensure the accuracy of ±1mm. |

| Cutting | Automatically stop and cutting when it comes to the set length. |

B.Components Details

| Roller Material | High grade 45# steel. Hard chrome plating, 0.05mm. |

| Main Frame | 350# steel. More stable and no shaking. |

| Middle Plate | 20mm. We use thicker plates to ensure stability of our products. |

| Forming Steps | 11-20 steps, according to the drawing. |

| Shaft Material | Φ70 mm, high grade 45# steel. Treating process: tempering- finish turning, high rigidity, hard to deform. |

Cutting Blade Material | Cr12, hardness HRC60-62. Treating process: heat treatment- plane abrasion- wire electrode cutting. |

C.Electric Components

| Suitable Power | 380V, 50 Hz, 3 phase or according to your need. |

| Screen | 7 inch touch screen, easy to operate.Brand Delta or based on your need |

| PLC | Delta Brand (Or Panasonic /Siemens ) Well-adapted to various conditions, such as moisture, electromagnetic disturbance. |

| Frequency Converter | delta; It has the advantage of slowing down before cutting, to ensure the length accuracy (±1mm, far better than industrial standard ±3mm). |

Length Measurement Device | Omron, made in Japan. It features with high accuracy and stability. |